As a professional filter cartridge factory, Paier utilizes advanced filtration technology imported from abroad, delivering oil-water separator filter cartridges with exceptional quality and performance. Known for high-efficiency separation and low flow resistance, Paier's oil-water separation cartridge products rival those of leading international brands, making them a trusted choice for diverse filtration needs.

Contact us today and get the details of our separator filter elements now!

Made with 200-mesh stainless steel coated with polytetrafluoroethylene (PTFE) on both sides, offering low flow resistance and high separation efficiency.

Designed to meet API-1581 and GTB610-88 standards, ensuring reliable performance and quality.

Available in a wide range of specifications and models to suit various filtration applications.

Teflon material provides excellent water resistance for effective separation.

Carbon steel inner frame ensures long-lasting support and extended lifespan.

Prevents water droplets from passing through while allowing smooth oil flow.

Designed to deliver reliable and efficient separation of water and oil.

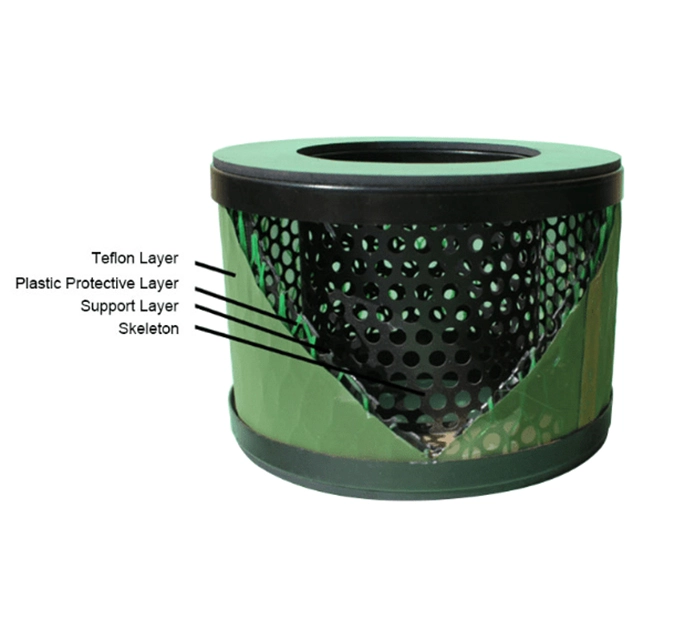

Paier's separator cartridges feature a Teflon Mesh with a natural hydrophobic property, effectively preventing droplets from passing through while handling higher flow rates.

The synthetic mesh is wrapped around a treated, perforated metal shell and adhesive-bonded to gasketed metal end caps, providing effective water-repelling characteristics for long, trouble-free service.

The separation cartridge also includes a Plastic Protection Mesh to safeguard the outer Teflon mesh, a Support Mesh for added stability, and an Inner Frame made of carbon steel to support the entire filter media and ensure structural integrity.

Paired with Coalescing Filter Elements, these separator cartridges are ideal for water removal in bulk fuel and aviation applications.

The Oil Water Separator Filter Cartridge is the second component of the coalescing filter, designed to separate water droplets from substances such as turbine oil, transformer oil, aviation fuel, gasoline, kerosene, diesel, tar, and naphtha. When used with different coalescing media, it can also be applied to other hydrocarbons, including liquefied petroleum gas (LPG), benzene, toluene, xylene, cumene, polypropene, cyclohexane, isopropanol, cyclohexanol, and cyclohexanone. This makes it an essential functional element of the coalescing filter.

The oil-water separator filter element is suitable for various coalescing filters used in both stationary and mobile facilities.

The separation filter element has good lipophilicity and hydrophobicity, so it can be used to further separate water and finally obtain clean and anhydrous oil. A separation filter element is often used for drying various gases. It can separate the fine water mist dispersed in the gas, which plays the role of drying and dehydration. At the same time, the separation cartridge can also be used to filter some liquid-liquid immiscible mixtures with large specific gravity differences.

Separating the filter element can also effectively keep the oil circuit inside the filter and prolong the service life of the filter. At the same time, it has good interchangeability. Some filter elements used in the low-pressure environment are also provided with bypass valves. When the filter elements are replaced in time, the bypass valves can automatically open, ensuring the normal operation of the filter system and effectively controlling the pollution degree of the working medium.

The oil water separator filter element operates by utilizing coalescence and separation principles. As oil-contaminated water flows through, the filter media causes small oil droplets to merge into larger ones, which are then separated from the water. The clean water exits the system, while the oil is either collected or disposed of.

Oil water separator filter cartridge is mainly designed for oil-water separation, and it contains two kinds of filter elements, namely, poly filter element and separation filter element. For example, in the oil water removal system, after the oil flows into the coalescence separator, it first flows through the coalescing filter element, which filters out solid impurities and coalesces tiny water droplets into larger water droplets. Most of the coalesced water droplets can be separated and removed from the oil by their own weight, and settled into the water collecting tank.

Oil-water separator Compressed air oil-water separator is composed of casing, cyclone separator, filter element, and blowdown parts. When the compressed air containing a large amount of oil and water solid impurities enters the air oil separator element, it spins down along its inner wall, resulting in centrifugal action, which makes the oil and water separate out from the steam flow and flow down the wall to the bottom of the oil-water separator filter cartridge, and then it is finely filtered by the filter element. As the filter element is made of coarse, fine, and superfine fiber filter materials, it has high filtration efficiency (up to 99.9%) and low resistance. When the gas passes through the filter element, it has firmly adhered to the fiber of the filter material due to the block of the filter element, inertial collision, intermolecular Van der Waals force, electrostatic attraction and vacuum attraction, and gradually increases into liquid drops, which drip into the bottom of the separator under gravity and are discharged by the sewage valve.